- Home

- Industries

- Incineration of agra waste

Incineration of agra waste

ecological utilisation of waste streams

Long life cycles, efficient safety and low emissions

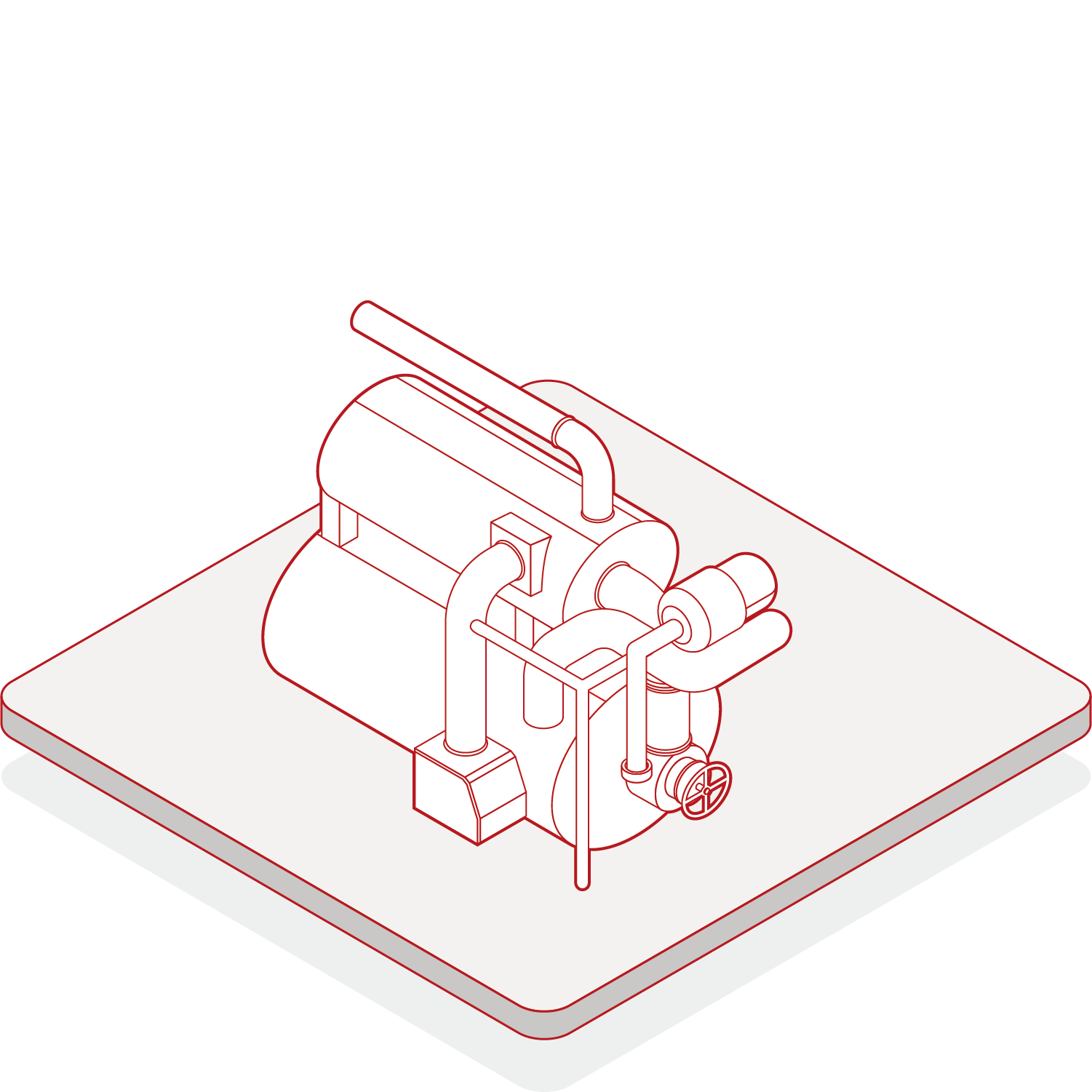

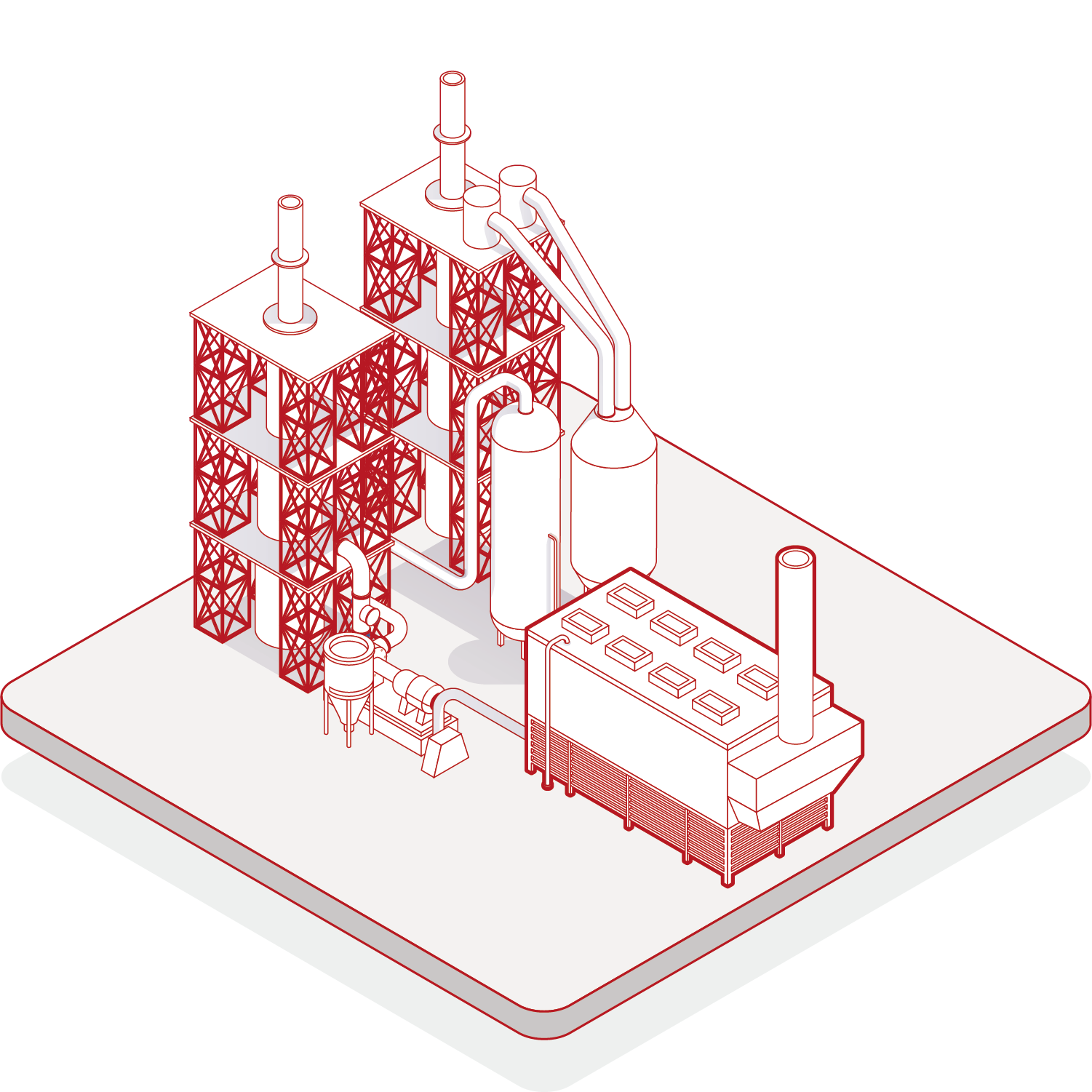

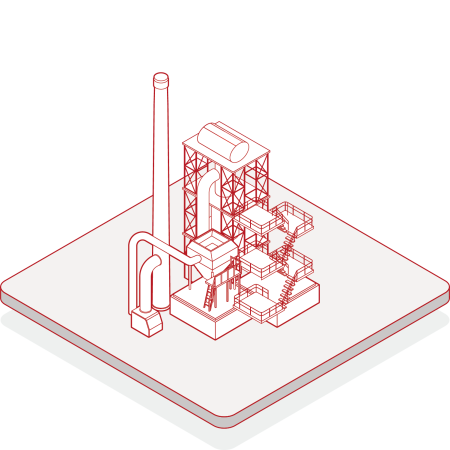

With our air-cooled reciprocating grate firing systems in both, inclined and level design, we can burn production waste and all types of biomass. These are mostly woody wastes from industrial production processes but also residues from agriculture and forestry.

Variations in calorific values, high moisture and ash contents, a wide range of fuel sizes and sometimes rather low ash softening temperatures place special demands on the design of the firing grates, of the combustion chamber, the fuel metering devices as well as on the combustion control along with the demand for complete burn-out and minimum emissions.

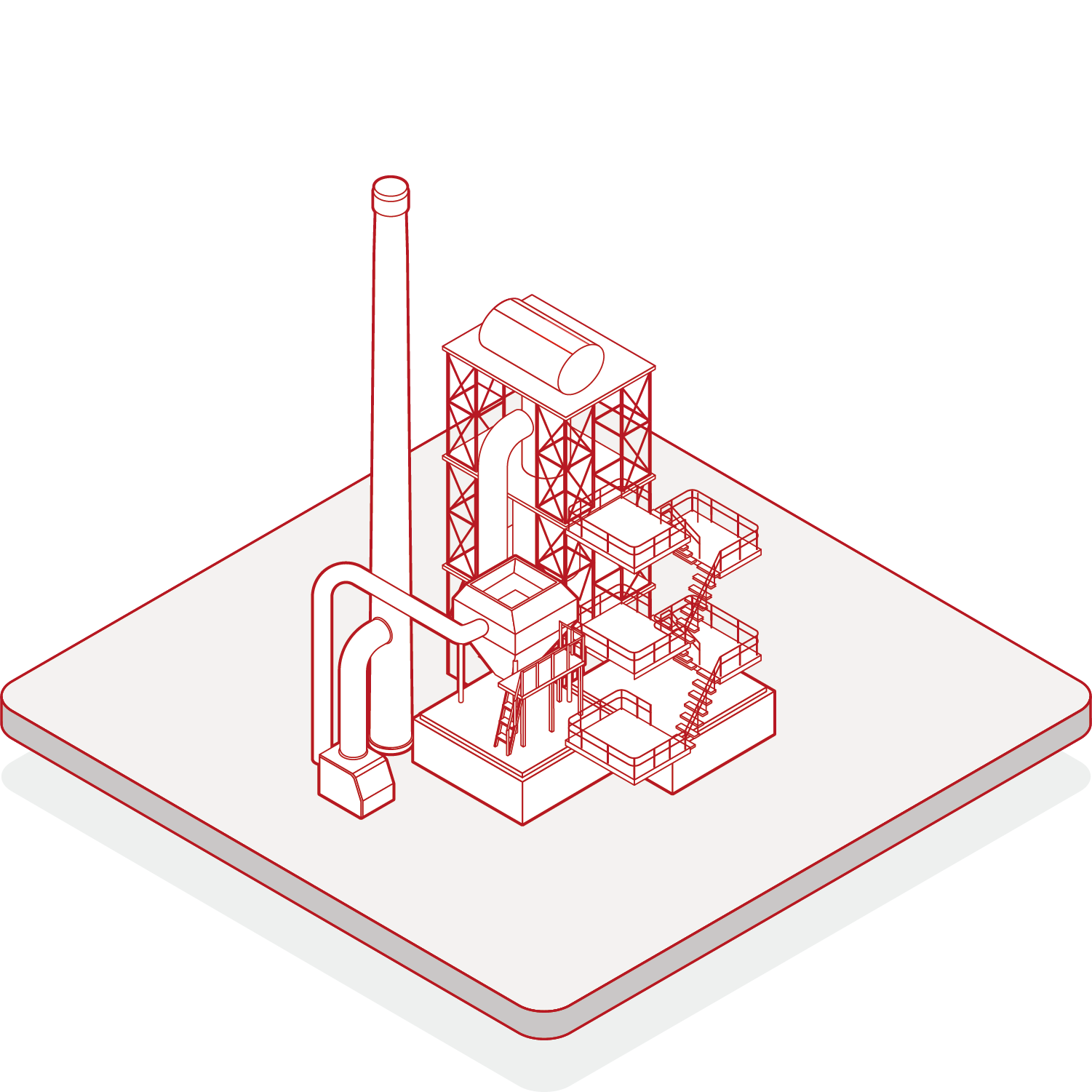

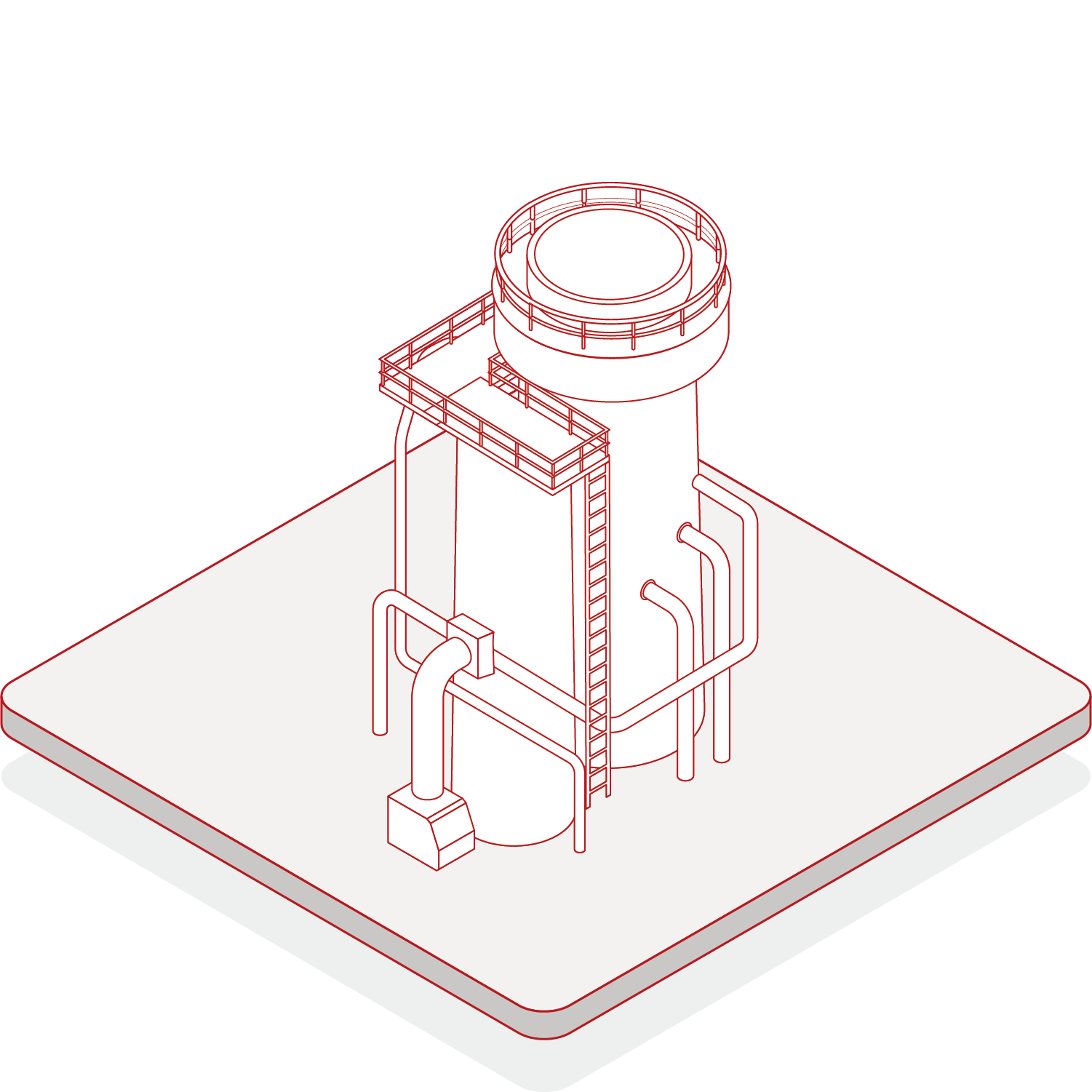

In the range of 4,000 to 60,000 kW in a single combustion chamber, we simultaneously generate process heat by means of thermal oil as well as steam and/or hot gas.Our KONTAKTOMAT® thermal oil heaters and waste heat recovery systems are equipped with highly efficient cleaning systems for maximum operating cycles without shut-downs, and automatic ash removal from the combustion chamber is a standard. Our firing and heater systems have demonstrated availabilities of > 8,200 operating hours per year in rough industrial day-to-day operation without being shut down for cleaning purposes. Not at least we consistently apply state-of-the-art automation and safety concepts as well as emission reduction measures.

For those wastes that are not suitable for incineration on our mechanical firing grates we combine both, rotary kiln incinerators as well as fluidized bed furnaces with our waste heat recovery systems.

References

Our experienced and competent staff will be happy to help you

Find out more about our industry solutions, give us a call or send us an e-mail.

Classen Apparatebau Wiesloch GmbH

Ludwig-Wagner-Str. 9/1

69168 Wiesloch

Germany

Telefon | |

Telefax | |

E-Mail | This email address is being protected from spambots. You need JavaScript enabled to view it. |